Vacuum carburizing furnace

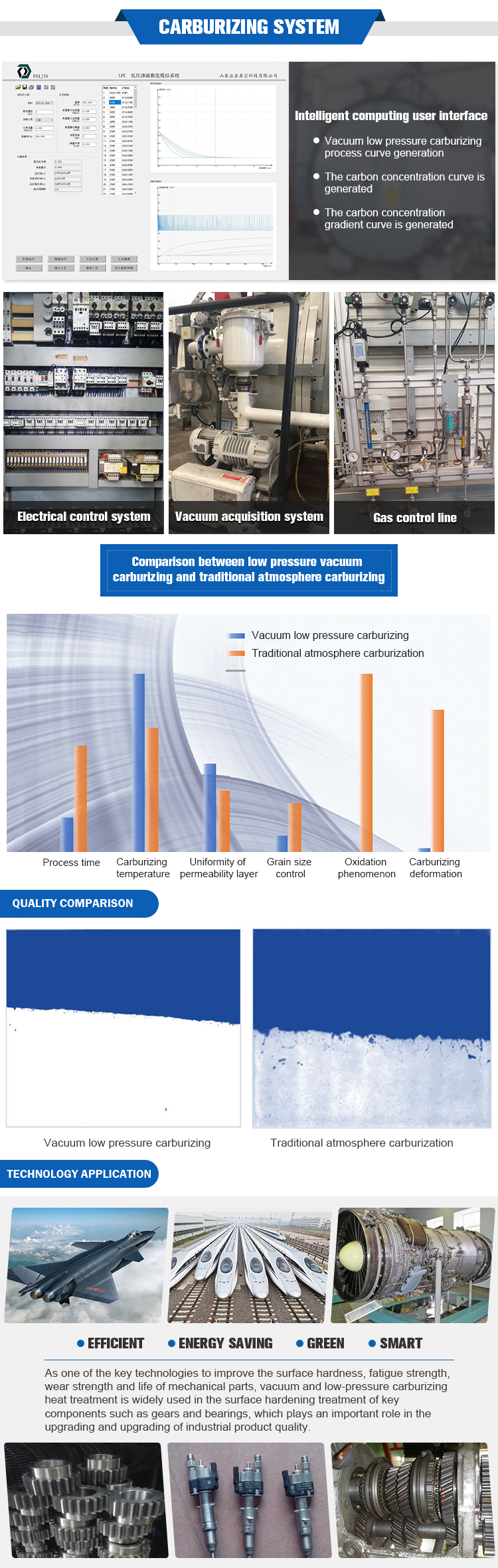

Vacuum carburizing is to heat the workpiece in vacuum. When it reaches the temperature above the critical point, it will stay for a period of time, degass and remove the oxide film, and then pass in the purified carburizing gas for carburizing and diffusion. The carburizing temperature of vacuum carburizing is high, up to 1030 ℃, and the carburizing speed is fast. The surface activity of carburized parts is improved by degassing and deoxidizing. The subsequent diffusion speed is too high. Carburizing and diffusion are carried out repeatedly and alternately until the required surface concentration and depth are reached.

Vacuum carburizing depth and surface concentration can be controlled; It can change the metallurgical properties of the surface layer of metal parts, and its effective carburizing depth is deeper than the actual carburizing depth of other methods.

Product Description

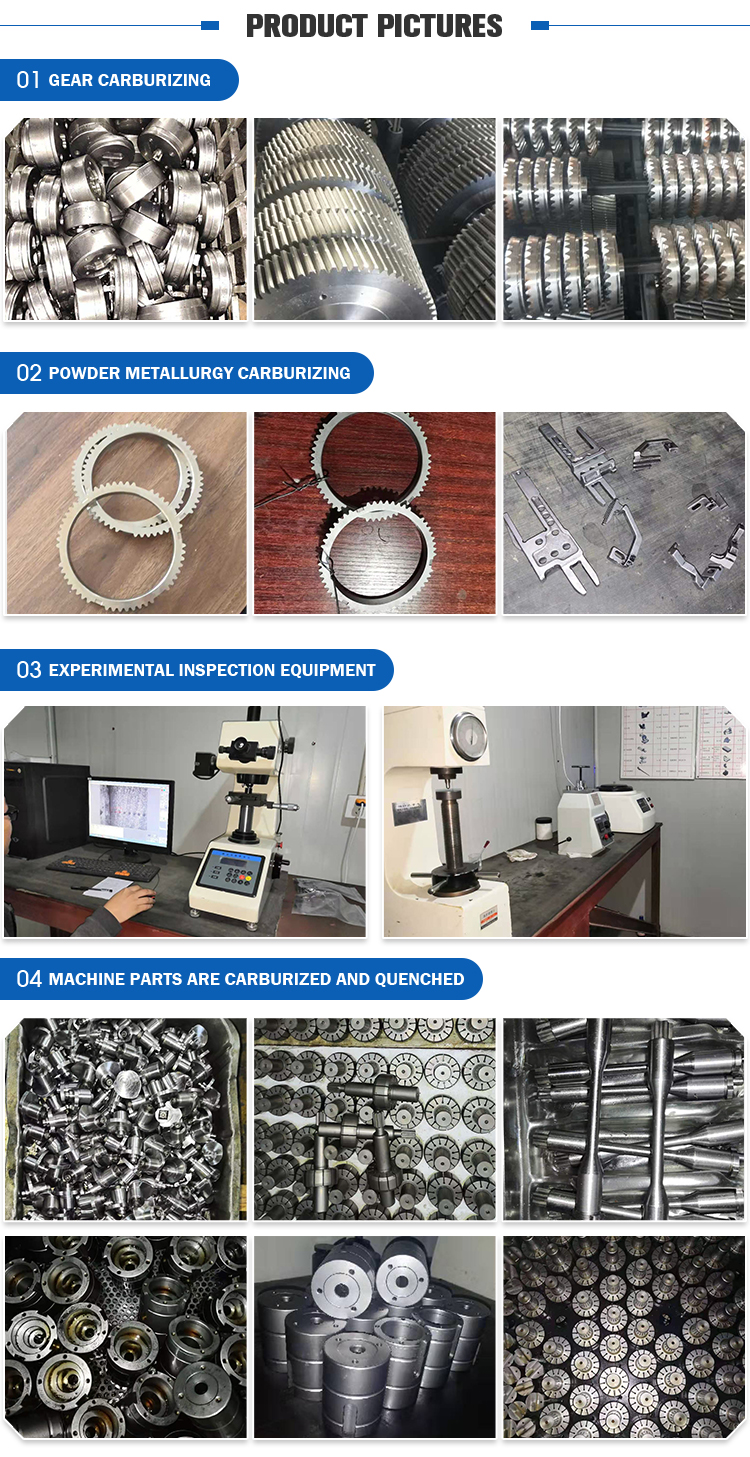

Single chamber horizontal low pressure Carburizing gas quenching furnace (air cooling by vertical gas flow type) has many functions like carburizing, gas quenching and pressure air-cooling.

Application

This furnace is mainly used for quenching, annealing,tempering of the die steel, the stainless steel, the high-speed steel, the higent processes like one-time high-carburizing, pulse carburizing and so on.

Characteristics

1. High intelligent and efficient. It is equipped special developed vacuum low-pressure carburizing simulation software.

2. High cooling rate. the cooling rate is increased by 80% by using high efficiency square heat exchanger.

3. Good cooling uniformity. Uniform cooling by convection from double-fans。

4. Good temperature uniformity. heating elements are evenly arranged 360 degrees around the heating chamber.

5.No carbon black pollution. The heating chamber adopts the external insulation structure to prevent the pollution of the carbon black in carburizing process.

6. Long service life , Using the carbon felt as the heat-insulation layer of the heating chamber.

7. Good carburized layer thickness uniformity, Carburizing gas nozzles are evenly arranged around the heating chamber, and the thickness of carburized layer is uniform.

8. Less deformation of the Carburizing workpiece , higher production efficiency and energy cost is saved more than 40%.

9. Smart and easy for process programming, stable and reliable mechanical action , automatically, semi-automatically or manually alarming and displaying the faults.

10. Frequency conversion control gas quenching fan, optional convection air heating, optional 9 points temperature survey, several grades and isothermal quenching.

11. With whole AI control system and an extra manual operating system.