News

-

Brazing of tool steel and cemented carbide

1. Brazing material (1) Brazing tool steels and cemented carbides usually use pure copper, copper zinc and silver copper brazing filler metals. Pure copper has good wettability to all kinds of cemented carbides, but the best effect can be obtained by brazing in the reducing atmosphere of hydrogen...Read more -

Brazing of carbon steel and low alloy steel

1. Brazing material (1) Brazing of carbon steel and low alloy steel includes soft brazing and hard brazing. The widely used solder in soft soldering is tin lead solder. The wettability of this solder to steel increases with the increase of tin content, so the solder with high tin content should ...Read more -

Four sintering processes of silicon carbide ceramics

Silicon carbide ceramics have high temperature strength, high temperature oxidation resistance, good wear resistance, good thermal stability, small coefficient of thermal expansion, high thermal conductivity, high hardness, heat shock resistance, chemical corrosion resistance and other excellent ...Read more -

Debinding & sintering

What’s Debinding & sintering: Vacuum debinding and sintering is a process required for many parts and applications, including powdered metal parts and MIM components, 3D metal printing, and beading applications like abrasives. The debind and sinter process masters complex manufacturing requir...Read more -

Carburizing & Nitriding

What’s Carburizing & Nitriding Vacuum Carburizing with Acetylene (AvaC) The AvaC vacuum carburizing process is a technology that uses acetylene to virtually eliminate the soot and tar formation problem known to occur from propane, while greatly increasing carburizing power even for blind or t...Read more -

Vacuum brazing for aluminium products and copper stainless steel etc

What’s Brazing Brazing is a metal-joining process in which two or more materials are joined when a filler metal (with a melting point lower than those of the materials themselves) is drawn into the joint between them by capillary action. Brazing has many advantages over other metal-joining techn...Read more -

Heat treatment, quenching tempering anealing normalizing ageing etc

What’s Quenching: Quenching, also called Hardening is the heating and subsequent cooling of steel at such a speed that there is a considerable increase in hardness, either on the surface or throughout. In the case of vacuum hardening, this process is done in vacuum furnaces in which temperatures ...Read more -

Vacuum quenching,bright quenching for metal alloy stainlesssteelHeat treatment,quenching for metal alloy stainlesssteel

Quenching, also called hardening is the process of heating and then cooling of steel (or other alloy) at a high speed that there is a much increase in hardness, either on the surface or throughout. In the case of vacuum Quenching, this process is done in vacuum furnaces in which temperatures of ...Read more -

What is the welding effect of vacuum brazing furnace

Brazing in vacuum furnace is a relatively new brazing method without flux under vacuum conditions. Because the brazing is in a vacuum environment, the harmful effect of air on the workpiece can be effectively eliminated, so the brazing can be carried out successfully without applying flux. It is ...Read more -

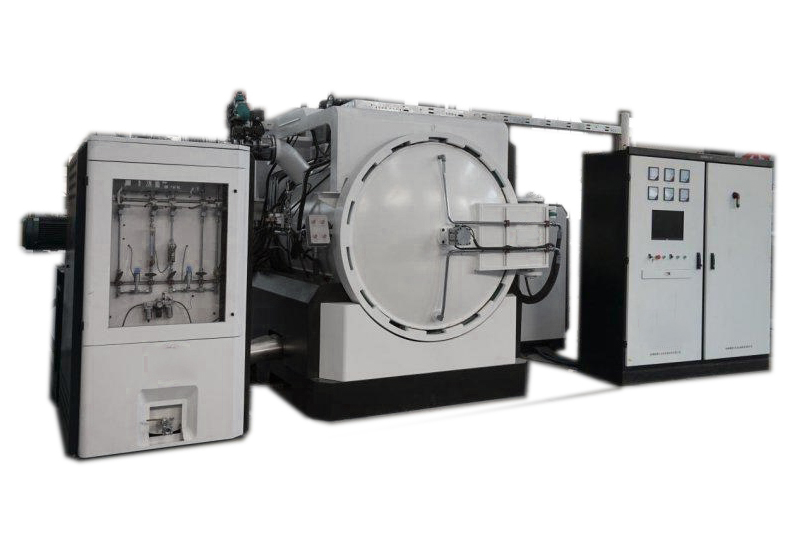

How to choose the right vacuum furnace for mass produce of parts

An important factor for the cost-effective operation of vacuum sintering furnace is the economic consumption of process gas and power. According to different gas types, these two cost elements of sintering process can account for 50% of the total cost. In order to save gas consumption, an adjust...Read more -

Daily use skills of vacuum sintering furnace

Vacuum sintering furnace is mainly used for the sintering process of semiconductor components and power rectifier devices. It can carry out vacuum sintering, gas protected sintering and conventional sintering. It is a novel process equipment in the special semiconductor equipment series. It has n...Read more