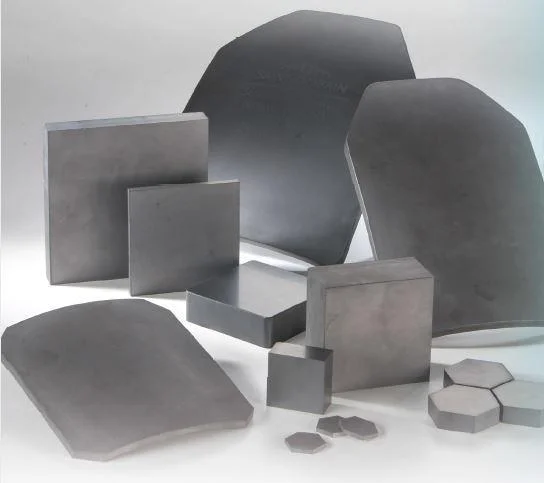

Silicon carbide ceramics have high temperature strength, high temperature oxidation resistance, good wear resistance, good thermal stability, small coefficient of thermal expansion, high thermal conductivity, high hardness, heat shock resistance, chemical corrosion resistance and other excellent properties. It has been widely used in automobile, mechanization, environmental protection, aerospace technology, information electronics, energy and other fields, and has become an irreplaceable structural ceramic with excellent performance in many industrial fields. Now let me show you!

Pressureless sintering

Pressureless sintering is considered as the most promising method for SiC sintering. According to different sintering mechanisms, pressureless sintering can be divided into solid-phase sintering and liquid-phase sintering. Through ultra-fine β- A proper amount of B and C (oxygen content less than 2%) were added to SiC powder at the same time, and s. proehazka was sintered to SiC sintered body with density higher than 98% at 2020 ℃. A. Mulla et al. Al2O3 and Y2O3 were used as additives and sintered at 1850-1950 ℃ for 0.5 μ m β- SiC (particle surface contains a small amount of SiO2). The relative density of the obtained SiC ceramics is greater than 95% of the theoretical density, and the grain size is small and the average size. It is 1.5 microns.

Hot press sintering

Pure SiC can only be sintered compactly at very high temperature without any sintering additives, so many people implement hot pressing sintering process for SiC. There have been many reports on the hot pressing sintering of SiC by adding sintering aids. Alliegro et al. Studied the effect of boron, aluminum, nickel, iron, chromium and other metal additives on SiC densification. The results show that aluminum and iron are the most effective additives to promote SiC hot pressing sintering. F. F.lange studied the effect of adding different amount of Al2O3 on the properties of hot pressed SiC. It is considered that the densification of hot pressed SiC is related to the mechanism of dissolution and precipitation. However, the hot press sintering process can only produce SiC parts with simple shape. The quantity of products produced by the one-time hot press sintering process is very small, which is not conducive to industrial production.

Hot isostatic pressing sintering

In order to overcome the shortcomings of traditional sintering process, B-type and C-type were used as additives and hot isostatic pressing sintering technology was adopted. At 1900 ° C, fine crystalline ceramics with a density greater than 98 were obtained, and the bending strength at room temperature could reach 600 MPa. Although hot isostatic pressing sintering can produce dense phase products with complex shapes and good mechanical properties, the sintering must be sealed, which is difficult to achieve industrial production.

Reaction sintering

Reaction sintered silicon carbide, also known as self bonded silicon carbide, refers to the process in which porous billet reacts with gas or liquid phase to improve billet quality, reduce porosity, and sinter finished products with certain strength and dimensional accuracy. take α- SiC powder and graphite are mixed in a certain proportion and heated to about 1650 ℃ to form a square billet. At the same time, it penetrates or penetrates into the billet through gaseous Si and reacts with graphite to form β- SiC, combined with existing α- SiC particles. When Si is completely infiltrated, the reaction sintered body with complete density and non shrinkage size can be obtained. Compared with other sintering processes, the size change of reaction sintering in the densification process is small, and the products with accurate size can be prepared. However, the existence of a large amount of SiC in the sintered body makes the high-temperature properties of reaction sintered SiC ceramics worse.

Post time: Jun-08-2022