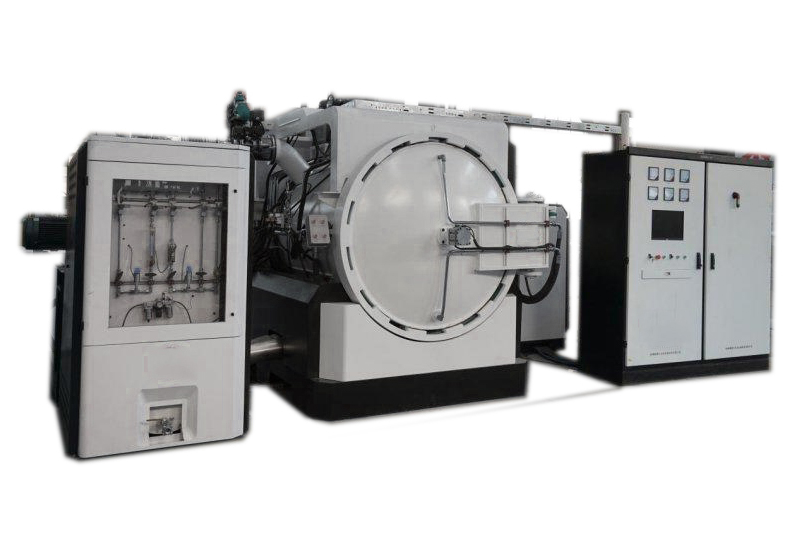

Vacuum sintering furnace is mainly used for the sintering process of semiconductor components and power rectifier devices. It can carry out vacuum sintering, gas protected sintering and conventional sintering. It is a novel process equipment in the special semiconductor equipment series. It has novel design concept, convenient operation and compact structure. Multiple process flows can be completed on one equipment. It can also be used in vacuum heat treatment, vacuum brazing and other processes in other fields.

Necessary skills for the use of vacuum sintering furnace

High vacuum sintering furnace is used to make the tungsten crucible in the coil produce high temperature under the protection of hydrogen filling after vacuum pumping and the principle of medium frequency induction heating, which is transmitted to the work through thermal radiation. It is suitable for the powder forming and sintering of refractory alloys such as tungsten, molybdenum and their alloys in scientific research and military industrial units. The place where the electric furnace is installed shall meet the requirements of vacuum hygiene, the surrounding air shall be clean and dry, and there shall be good ventilation conditions. The work site is not easy to raise dust, etc.

Daily use skills of vacuum sintering furnace:

1. Check whether all components and accessories in the control cabinet are complete and intact.

2. The control cabinet shall be installed on the corresponding foundation and fixed.

3. According to the wiring diagram and referring to the electrical schematic diagram, connect the external main circuit and control circuit, and reliably grounded to ensure correct wiring.

4. Check that the movable part of the electrical appliance should move freely without jamming.

5. The insulation resistance shall not be less than 2 megohm.

6. All valves of vacuum electric furnace must be in the closed position.

7. Put the control power switch in the off position.

8. Turn the manual pressure regulating knob counterclockwise.

9. Put the alarm button in the open position.

10. Complete the circulating cooling water connection of the equipment according to the plan. It is recommended that the user connect another standby water (tap water available) at the main inlet and outlet pipe of the equipment to prevent the sealing ring from burning out due to the failure of circulating water or power failure.

Post time: May-07-2022