Good User Reputation forMaintenance Of Heat Treatment Equipment- Low temperature vacuum brazing furance – Paijin

Good User Reputation forMaintenance Of Heat Treatment Equipment- Low temperature vacuum brazing furance – Paijin Detail:

Application

It is mainly used for vacuum brazing and heat treatment of aluminum alloy products such as automobile radiator, air conditioning evaporator, condenser, radar network antenna and so on.

Characteristics

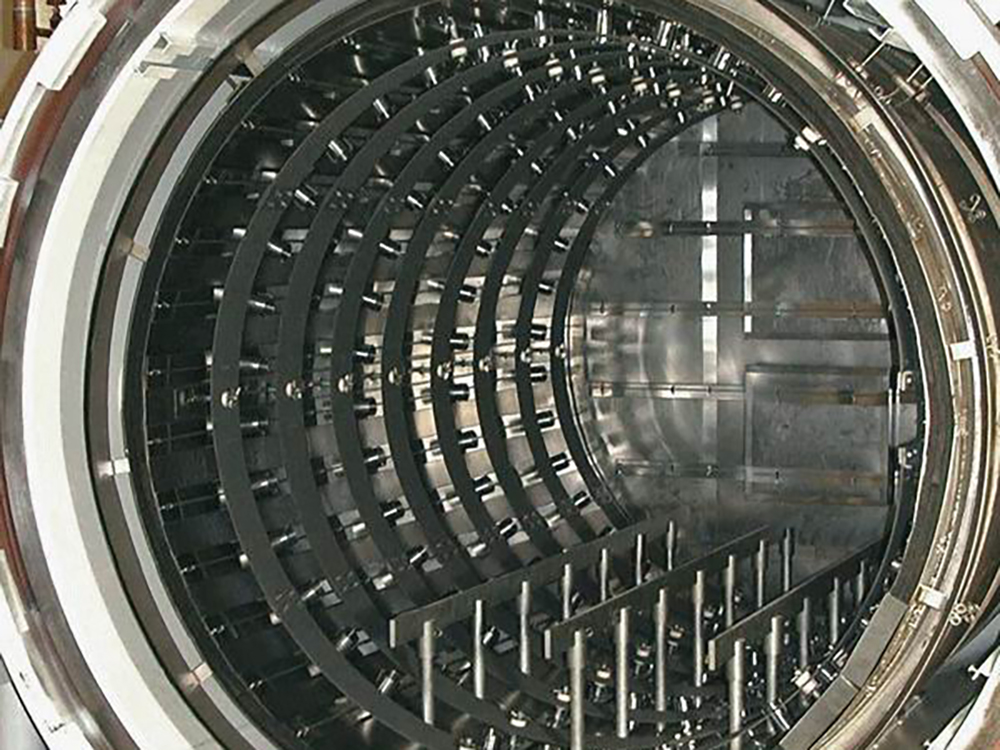

★Square chamber design, reflective metal heat shield, 360 degree surround radiation heating

★ Multi-zones independent temperature control, convective heating , vacuum partial pressure

★ Internal and external circulating cooling mode

★ Add vacuum condensation and Collector at exhaust Port

★ Fast recovery time of High vacuum system

★ Accurate process control achieves consistent product reproducibility

Standard model specification and parameters

| Model | PJ-LQ5510 | PJ-LQ9920 | PJ-LQ1225 | PJ-LQ1530 | PJ-LQ2250 |

| Effective Hot Zone WHL (mm) | 500*500* 1000 | 900*900* 2000 | 1200*1200* 2500 | 1500*1500* 3000 | 2000*2000* 5000 |

| Load Weight(kg) | 500 | 1200 | 2000 | 3500 | 4800 |

| Maximum Temperature(℃) | 700 | ||||

| Temperature control accuracy(℃) | ±1 | ||||

| Furnace temperature uniformity(℃) | ±3 | ||||

| Maximum Vacuum Degree(Pa) | 6.7 * E -3 | ||||

| Pressure raise rate (Pa/H) | ≤ 0.5 | ||||

| Air cooling pressure | 2 | ||||

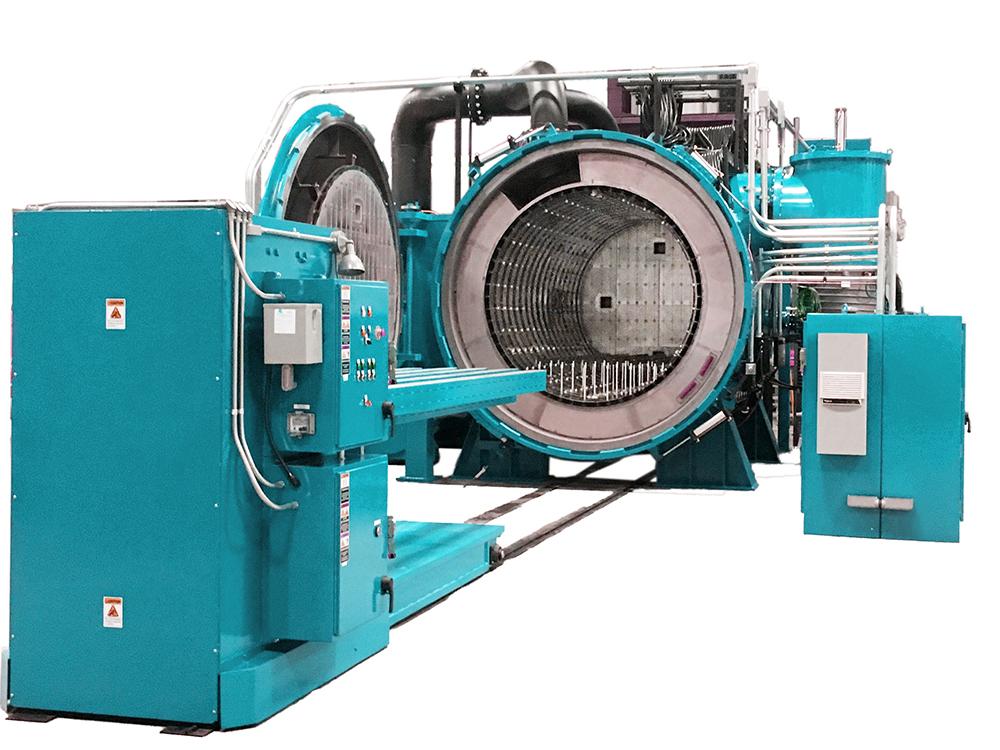

| Furnace structure | Horizontal, single chamber | ||||

| Furnace door opening method | Hinge type | ||||

| Heating elements | Ni Strip heating element | ||||

| Heating chamber | Metal Insulation screen | ||||

| PLC & Electric elements | Siemens | ||||

| Temperature controller | EUROTHERM | ||||

| Vacuum pump | Mechanical pump, roots pump,diffusion pump | ||||

| Customized optional ranges | |||||

| Furnace structure | Horizontal,Vertical, single chamber or multi chambers | ||||

| Door opening method | Hinge type, Lifting type,Flat type | ||||

| Heating elements | Ni Strip heating element, Mo heating elements | ||||

| PLC & Electric elements | Siemens;Omron;Mitsubishi;Siemens | ||||

| Temperature controller | EUROTHERM;SHIMADEN | ||||

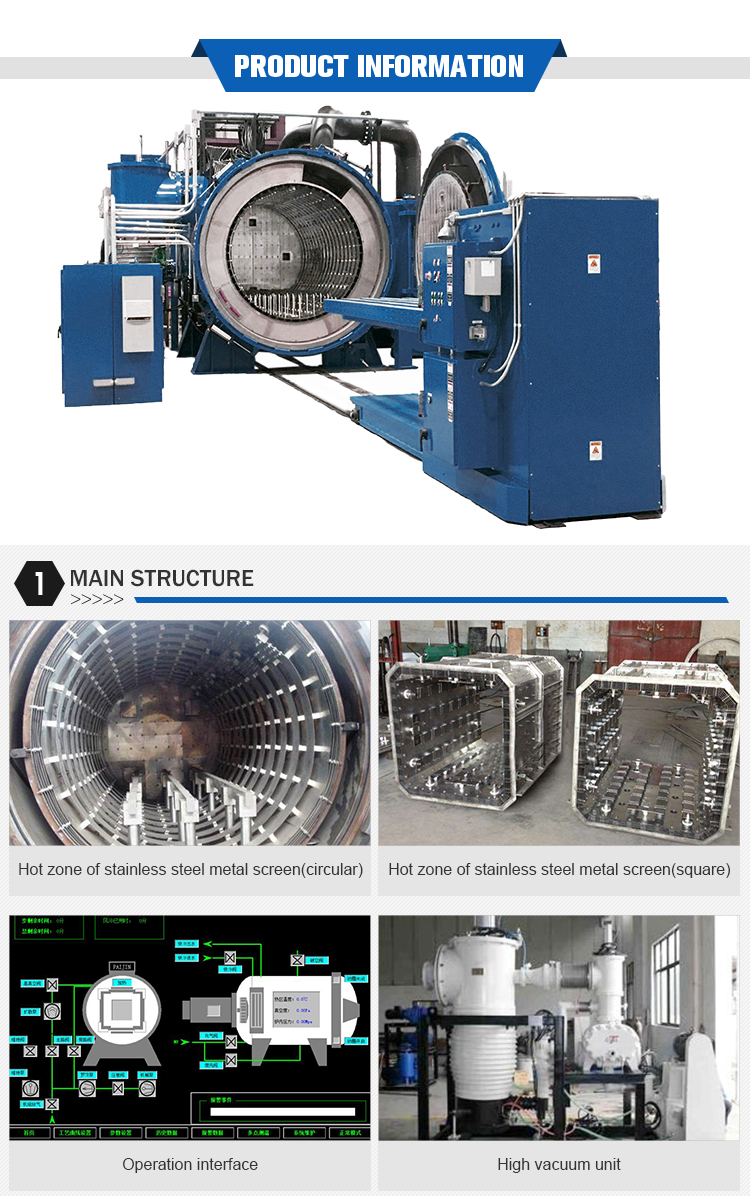

Product detail pictures:

Related Product Guide:

We are convinced that with joint efforts, the business between us will bring us mutual benefits. We can assure you product quality and competitive price for Good User Reputation forMaintenance Of Heat Treatment Equipment- Low temperature vacuum brazing furance – Paijin , The product will supply to all over the world, such as: Thailand, Orlando, South Africa, Our team knows well the market demands in different countries, and is capable of supplying suitable quality products at the best prices to different markets. Our company has already set up a professional, creative and responsible team to develop clients with the multi-win principle.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.

Write your message here and send it to us