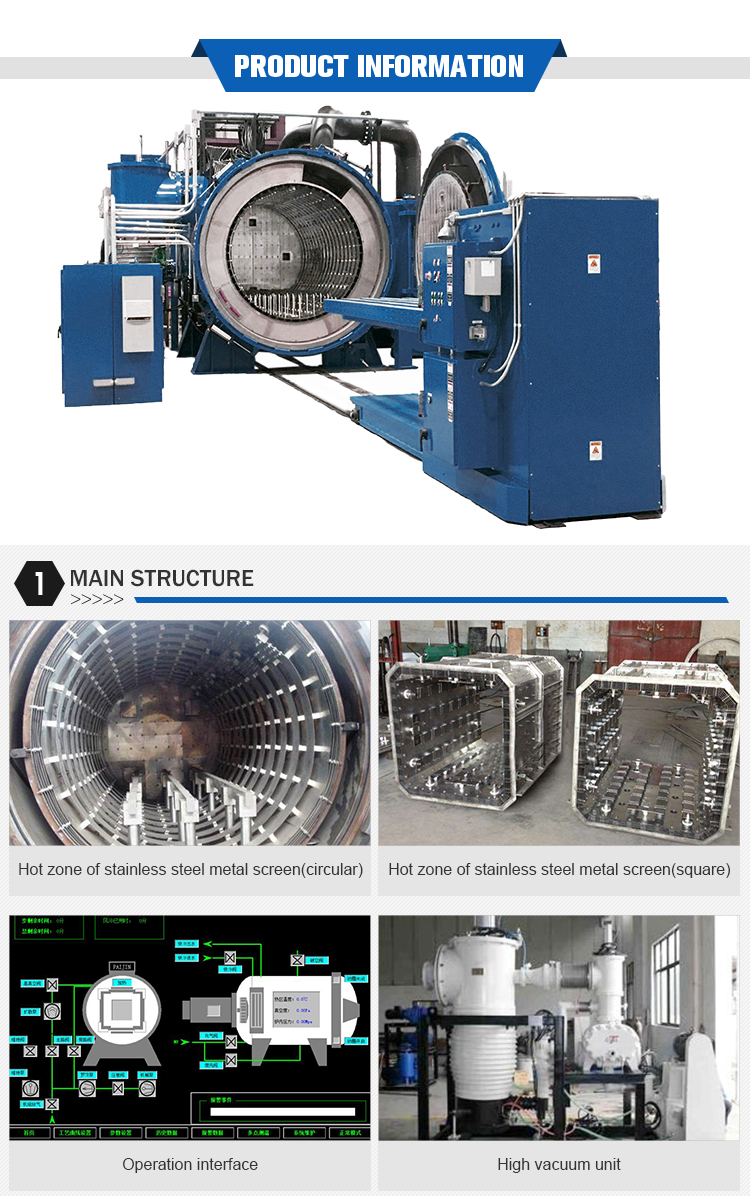

China Cheap priceCarburizing Well Vacuum Furnace- Low temperature vacuum brazing furance – Paijin

China Cheap priceCarburizing Well Vacuum Furnace- Low temperature vacuum brazing furance – Paijin Detail:

Application

It is mainly used for vacuum brazing and heat treatment of aluminum alloy products such as automobile radiator, air conditioning evaporator, condenser, radar network antenna and so on.

Characteristics

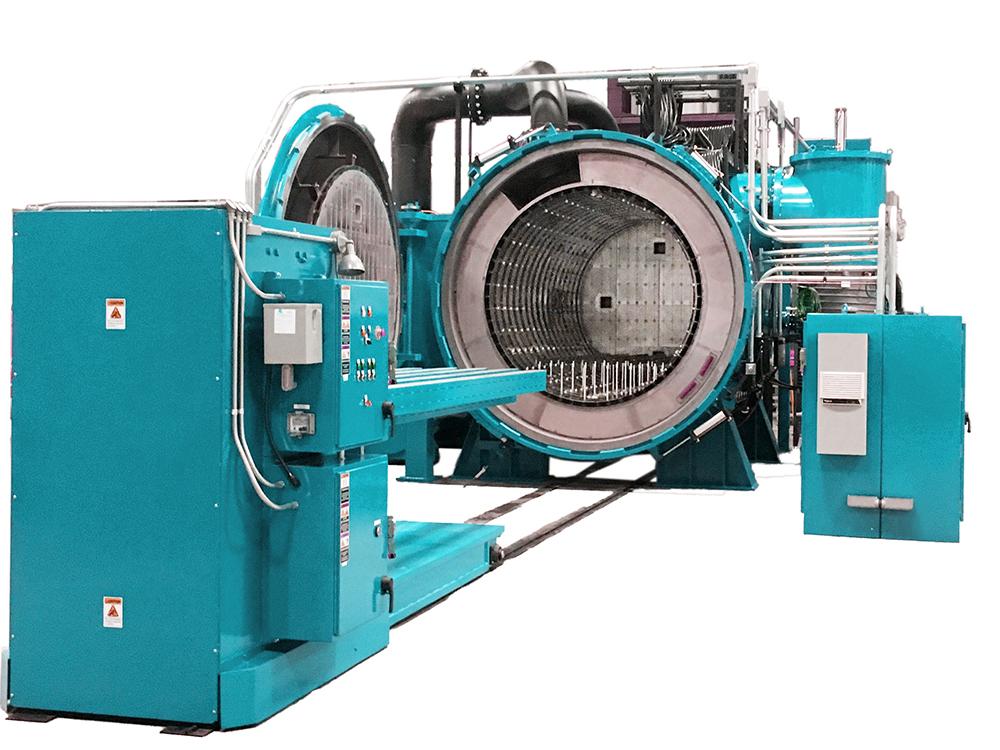

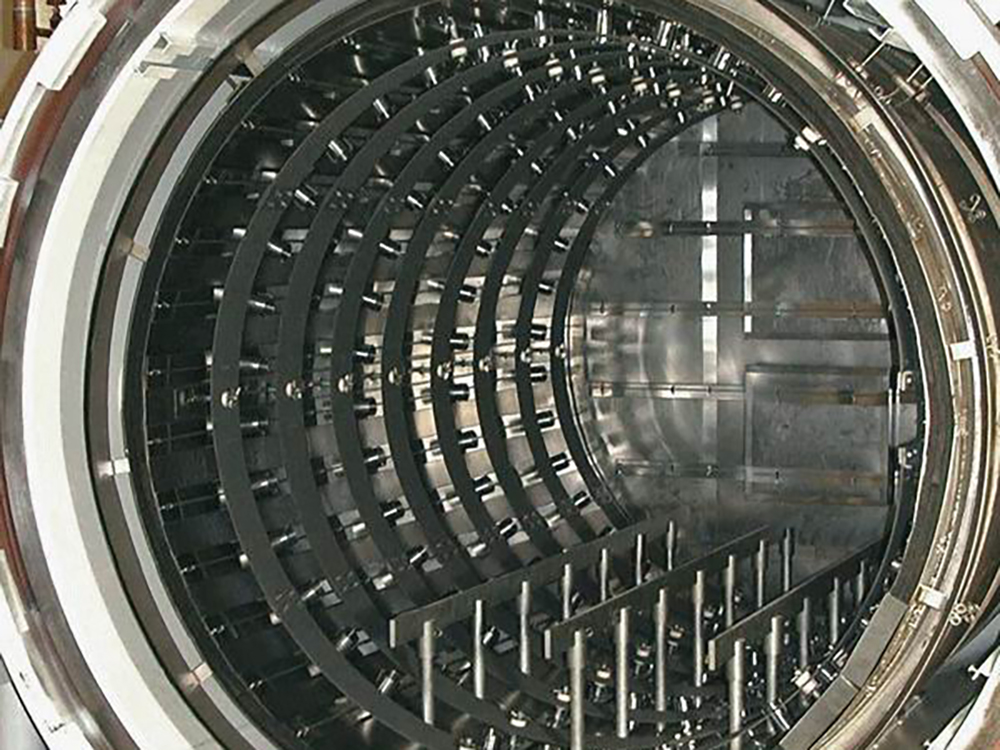

★Square chamber design, reflective metal heat shield, 360 degree surround radiation heating

★ Multi-zones independent temperature control, convective heating , vacuum partial pressure

★ Internal and external circulating cooling mode

★ Add vacuum condensation and Collector at exhaust Port

★ Fast recovery time of High vacuum system

★ Accurate process control achieves consistent product reproducibility

Standard model specification and parameters

| Model | PJ-LQ5510 | PJ-LQ9920 | PJ-LQ1225 | PJ-LQ1530 | PJ-LQ2250 |

| Effective Hot Zone WHL (mm) | 500*500* 1000 | 900*900* 2000 | 1200*1200* 2500 | 1500*1500* 3000 | 2000*2000* 5000 |

| Load Weight(kg) | 500 | 1200 | 2000 | 3500 | 4800 |

| Maximum Temperature(℃) | 700 | ||||

| Temperature control accuracy(℃) | ±1 | ||||

| Furnace temperature uniformity(℃) | ±3 | ||||

| Maximum Vacuum Degree(Pa) | 6.7 * E -3 | ||||

| Pressure raise rate (Pa/H) | ≤ 0.5 | ||||

| Air cooling pressure | 2 | ||||

| Furnace structure | Horizontal, single chamber | ||||

| Furnace door opening method | Hinge type | ||||

| Heating elements | Ni Strip heating element | ||||

| Heating chamber | Metal Insulation screen | ||||

| PLC & Electric elements | Siemens | ||||

| Temperature controller | EUROTHERM | ||||

| Vacuum pump | Mechanical pump, roots pump,diffusion pump | ||||

| Customized optional ranges | |||||

| Furnace structure | Horizontal,Vertical, single chamber or multi chambers | ||||

| Door opening method | Hinge type, Lifting type,Flat type | ||||

| Heating elements | Ni Strip heating element, Mo heating elements | ||||

| PLC & Electric elements | Siemens;Omron;Mitsubishi;Siemens | ||||

| Temperature controller | EUROTHERM;SHIMADEN | ||||

Product detail pictures:

Related Product Guide:

Our enterprise since its inception, often regards solution excellent as enterprise life, continually strengthen output technology, enhance product high quality and continually strengthen organization total high-quality administration, in strict accordance using the national standard ISO 9001:2000 for China Cheap priceCarburizing Well Vacuum Furnace- Low temperature vacuum brazing furance – Paijin , The product will supply to all over the world, such as: Afghanistan, Lithuania, Johor, We'd like to invite customers from abroad to discuss business with us. We can present our clients with high quality products and excellent service. We're sure that we'll have good cooperative relationships and make a brilliant future for both parties.

This is a very professional and honest Chinese supplier, from now on we fell in love with the Chinese manufacturing.

Write your message here and send it to us