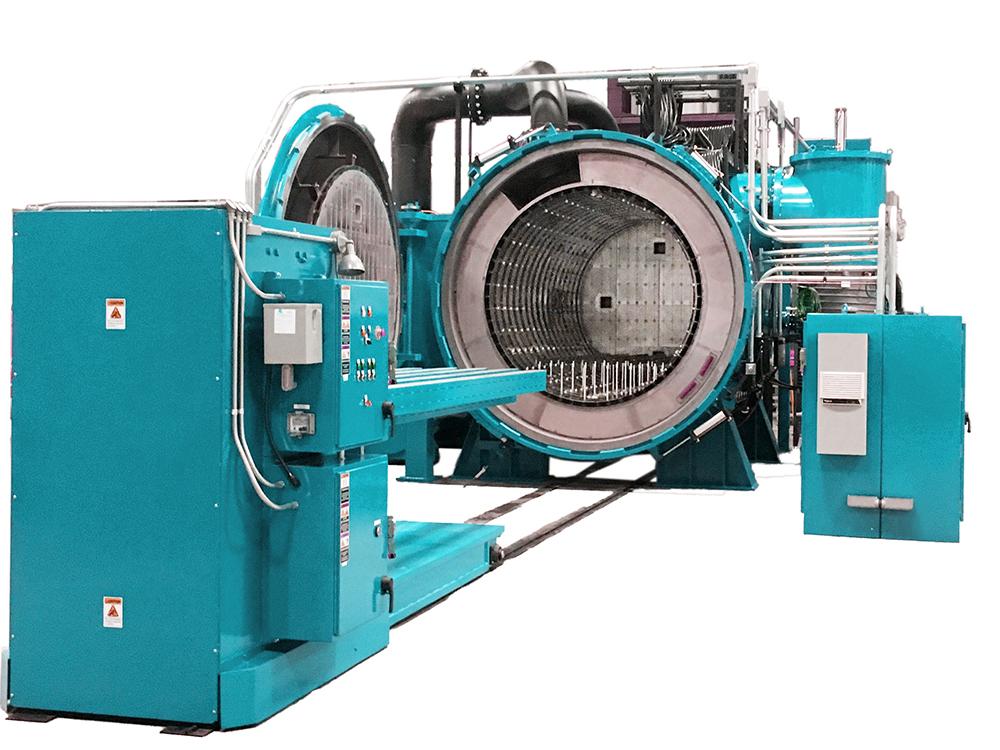

China Cheap price Isostatic Pressure Vacuum Sintering Furnace - High Temperature Vacuum Debinding and Sintering furnace – Paijin

China Cheap price Isostatic Pressure Vacuum Sintering Furnace - High Temperature Vacuum Debinding and Sintering furnace – Paijin Detail:

Characteristics

1. High temperature uniformity and thermal efficiency

2. Multi-zone independent temperature control, vacuum partial pressure function

3. The main body adopts high temperature resistant material, which satisfies the carbonation heating process of thin and medium and thick granule WC powder and composite material.

4.Adopt the combination mode of temperature control。

5.Graphite heat shield, graphite heating element,360-degree surround radiant heating.

6.A variety of condensation trapping methods to reduce unit pollution

7.Nitrogen purging system has better insulation and degreasing.

8.Patented insulation technology to ensure the long-term use of heating body

9.Exhaust gas combustion and filtration system meets emission standard

Standard model specification and parameters

| Model | PJSJ-gr-30-1600 | PJSJ-gr-60-1600 | PJSJ-gr-100-1600 | PJSJ-gr-200-1600 | PJSJ-gr-450-1600 |

| Effective Hot Zone LWH (mm) | 200*200*300 | 300*300*600 | 300*300*900 | 400*400*1200 | 500*500*1800 |

| Load Weight(kg) | 100 | 200 | 400 | 600 | 10000 |

| Heating Power (kw) | 65 | 80 | 150 | 200 | 450 |

| Maximum Temperature(℃) | 1600 | ||||

| Temperature control accuracy(℃) | ±1 | ||||

| Furnace temperature uniformity(℃) | ±3 | ||||

| Work Vacuum Degree(Pa) | 4.0 * E -1 | ||||

| Pumping rates(to 5 pa) | ≤10 min | ||||

| Pressure raise rate (Pa/H) | ≤ 0.5 | ||||

| Debinding rate | >97.5% | ||||

| Debinding method | N2 in negative pressure,H2 in atmosphere | ||||

| Input gas | N2,H2,Ar | ||||

| Cooling method | inert gas cooling | ||||

| Sintering method | Vacuum sintering,partial pressure sintering,pressureless sintering | ||||

| Furnace structure | Horizontal, single chamber | ||||

| Furnace door opening method | Hinge type | ||||

| Heating elements | Graphit heating elements | ||||

| Heating chamber | Composition structure of Graphit hard felt and soft felt | ||||

| Thermocouple | C Type | ||||

| PLC & Electric elements | Siemens | ||||

| Temperature controller | EUROTHERM | ||||

| Vacuum pump | Mechanical pump and roots pump | ||||

Customized optional ranges

| Maximum temperature | 1300-2800 ℃ | ||||

| Maximum temperature degree | 6.7 * E -3 Pa | ||||

| Furnace structure | Horizontal,Vertical, single chamber | ||||

| Door opening method | Hinge type, Lifting type,Flat type | ||||

| Heating elements | Graphit heating elements, Mo heating elements | ||||

| Heating chamber | Composed Graphit felt, All metal reflecting screen | ||||

| Vacuum pumps | Mechanical pump and roots pump; Mechanical, roots and diffusion pumps | ||||

| PLC & Electric elements | Siemens;Omron;Mitsubishi;Siemens | ||||

| Temperature controller | EUROTHERM;SHIMADEN | ||||

Product detail pictures:

Related Product Guide:

Our pursuit and firm aim should be to "Always fulfill our buyer requirements". We carry on to produce and structure top-quality excellent solutions for equally our aged and new consumers and accomplish a win-win prospect for our consumers as well as us for China Cheap price Isostatic Pressure Vacuum Sintering Furnace - High Temperature Vacuum Debinding and Sintering furnace – Paijin , The product will supply to all over the world, such as: Kuwait, Senegal, Gabon, Since our establishment, we keep on improving our products and customer service. We are able to provide you with a wide range of high quality hair products at competitive prices. Also we can produce different hair products according to your samples. We insist on high quality and reasonable price. Except this, we provide best OEM service. We warmly welcome OEM orders and customers all over the world to cooperate with us for mutual development in the future.

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.