2022 Good Quality SiC Vacuum Sintering Furnace - Vacuum Debinding and Sintering furnace (MIM Furnace, Powder metallurgy furnace) – Paijin

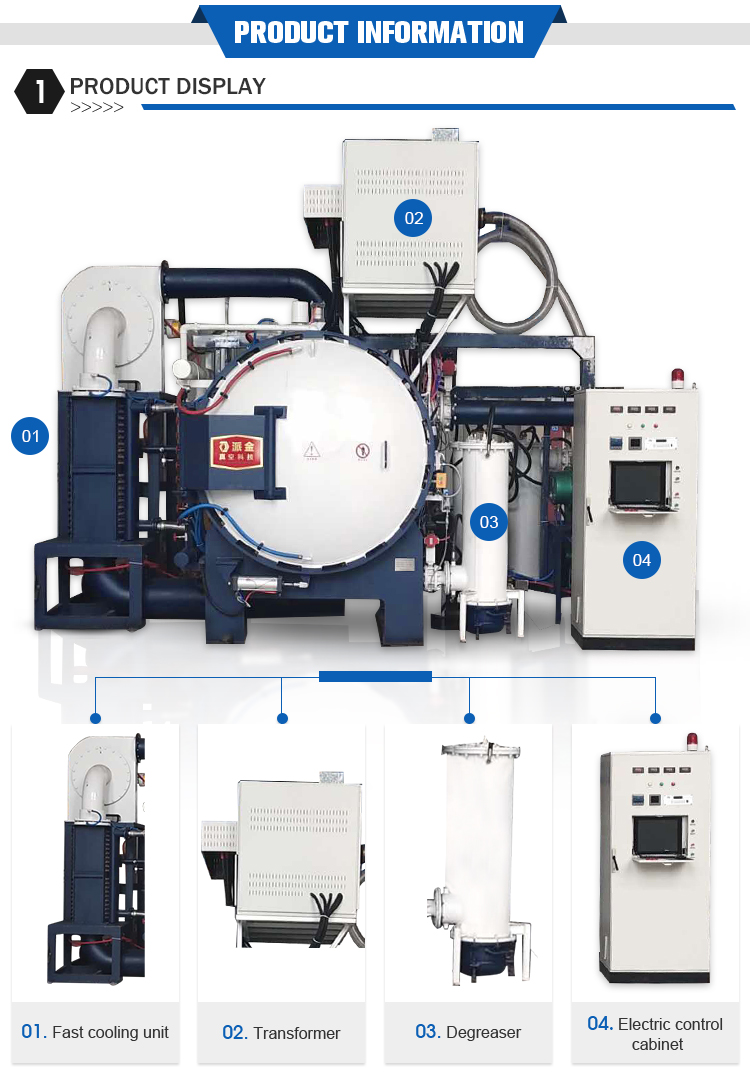

2022 Good Quality SiC Vacuum Sintering Furnace - Vacuum Debinding and Sintering furnace (MIM Furnace, Powder metallurgy furnace) – Paijin Detail:

Characteristics

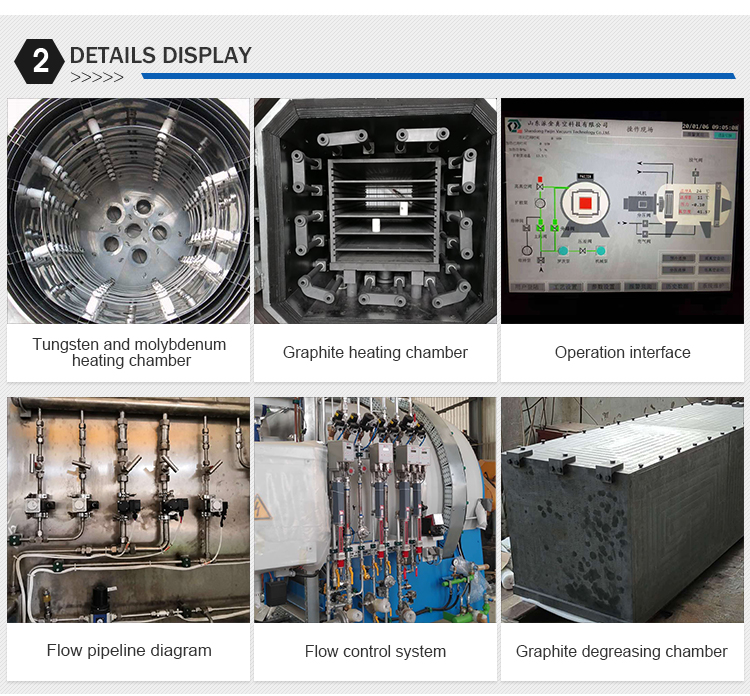

1. Graphite insulation screen / metal screen optional, heating element 360 degree surround radiation heating, reliable insulation design.

2. Higher temperature uniformity and thermal efficiency

3. Vacuum partial pressure / multi-area temperature control function.

4. Fully automated equipment, perfect safety and abnormal alarm system.

5. Accurate process control to achieve consistent part quality and prevent pollution of parts and hot areas.

6. With sealed degreasing box and vacuum condenser to reduce pollution of heating chamber and unit.

7.Prevent pollution to the components in the furnace. The square degreasing box is used to deal with large number of molding additives.

8. It has the functions of flexible vacuum extraction, vacuum sintering, micro-positive pressure sintering and so on.

9. The latest thermal insulation structure and materials is used, the pressure resistance is strong, and the energy saving is obvious.

10.It has the functions of overtemperature and overpressure alarm, mechanical automatic pressure protection, automatic overpressure relief protection, action interlock and so on, high equipment safety.

11.Remote operation, remote fault diagnosis and remote software upgrade functions,etc.

Standard model specification and parameters

| Model | PJSJ-gr-30-1600 | PJSJ-gr-60-1600 | PJSJ-gr-100-1600 | PJSJ-gr-200-1600 | PJSJ-gr-450-1600 |

| Effective hot zone LWH (mm) | 200*200* 300 | 300*300* 600 | 300*300* 900 | 400*400* 1200 | 500*500* 1800 |

| Load weight(kg) | 100 | 200 | 400 | 600 | 10000 |

| Heating power (kw) | 65 | 80 | 150 | 200 | 450 |

| Maximum temperature(℃) | 1600 | ||||

| Temperature control accuracy(℃) | ±1 | ||||

| Furnace temperature uniformity(℃) | ±3 | ||||

| Work vacuum degree(Pa) | 4.0 * E -1 | ||||

| Pumping rates(to 5 pa) | ≤10 min | ||||

| Pressure raise rate (Pa/H) | ≤ 0.5 | ||||

| Debinding rate | >97.5% | ||||

| Debinding method | N2 in negative pressure,H2 in atmosphere | ||||

| Input gas | N2,H2,Ar | ||||

| Cooling method | inert gas cooling | ||||

| Sintering method | Vacuum sintering,partial pressure sintering,pressureless sintering | ||||

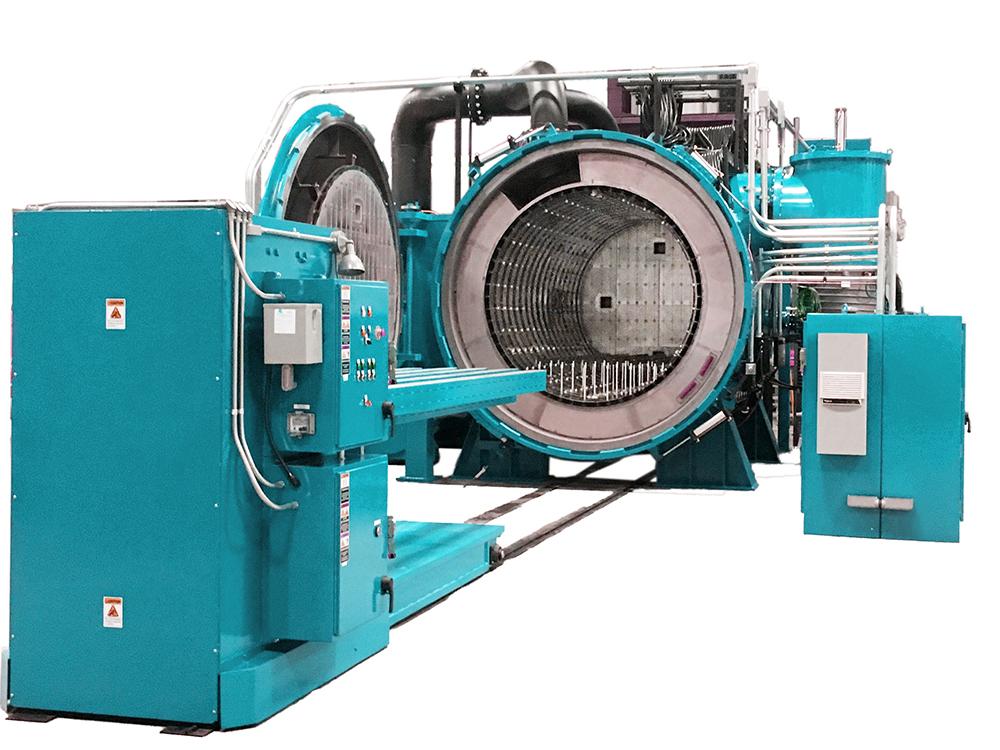

| Furnace structure | Horizontal, single chamber | ||||

| Furnace door opening method | Hinge type | ||||

| Heating elements | Graphit heating elements | ||||

| Heating chamber | Composition structure of Graphit hard felt and soft felt | ||||

| Thermocouple | C Type | ||||

| PLC & electric elements | Siemens | ||||

| Temperature controller | EUROTHERM | ||||

| Vacuum pump | Mechanical pump and roots pump | ||||

| Customized optional ranges | |||||

| Maximum temperature | 1300-2800 ℃ | ||||

| Maximum temperature degree | 6.7 * E -3 Pa | ||||

| Furnace structure | Horizontal,Vertical, Single chamber | ||||

| Door opening method | Hinge type, Lifting type, Flat type | ||||

| Heating elements | Graphit heating elements, Mo heating elements | ||||

| Heating chamber | Composed graphit felt, All metal reflecting screen | ||||

| Vacuum pumps | Mechanical pump and roots pump; Mechanical, Roots and diffusion pumps | ||||

| PLC & electric elements | Siemens; Omron; Mitsubishi; Siemens | ||||

| Temperature controller | EUROTHERM;S HIMADEN | ||||

Product detail pictures:

Related Product Guide:

With this motto in mind, we've turn into one of quite possibly the most technologically innovative, cost-efficient, and price-competitive manufacturers for 2022 Good Quality SiC Vacuum Sintering Furnace - Vacuum Debinding and Sintering furnace (MIM Furnace, Powder metallurgy furnace) – Paijin , The product will supply to all over the world, such as: Paraguay, Honduras, Casablanca, By integrating manufacturing with foreign trade sectors, we can present total customer solutions by guaranteeing the delivery of right merchandise to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified products and the control of the industry trend as well as our maturity before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

This is a honest and trustworthy company, technology and equipment are very advanced and the prodduct is very adequate, there is no worry in the suppliment.